The basics of British Laser Etching systems

Lasers are one of the most versatile technologies in the world. Laser technology is heavily used in a wide range of fields, from medicine to construction and everything in between. Once only a mainstay of villains in spy movies and alien invaders in science fiction, this flexible and powerful technology has made its mark on countless areas of modern life.

Speaking of making a mark, one area in which lasers can be particularly effective in is etching and engraving. Laser marking allows for precise designs to be permanently imprinted on nearly any material, including strong wood and dense metals. The uses for laser etching and engraving are nearly as wide-ranging as the uses for lasers in many other fields.

However, if you are looking to purchase one of these machines for your business, it can be difficult to know where to begin. Even those who have some familiarity with laser etching systems should realize that the technology moves very quickly, and it is very important to do your research into new models before making a purchase.

While there are many great styles and brands, British made laser cutter engravers have taken some major steps to move the technology forward and are becoming known as the premier machines in the field. With that in mind, this article will focus mainly on machines of British origins. But before we get into the specifics, it is important to understand the basics.

How does Laser Etching work?

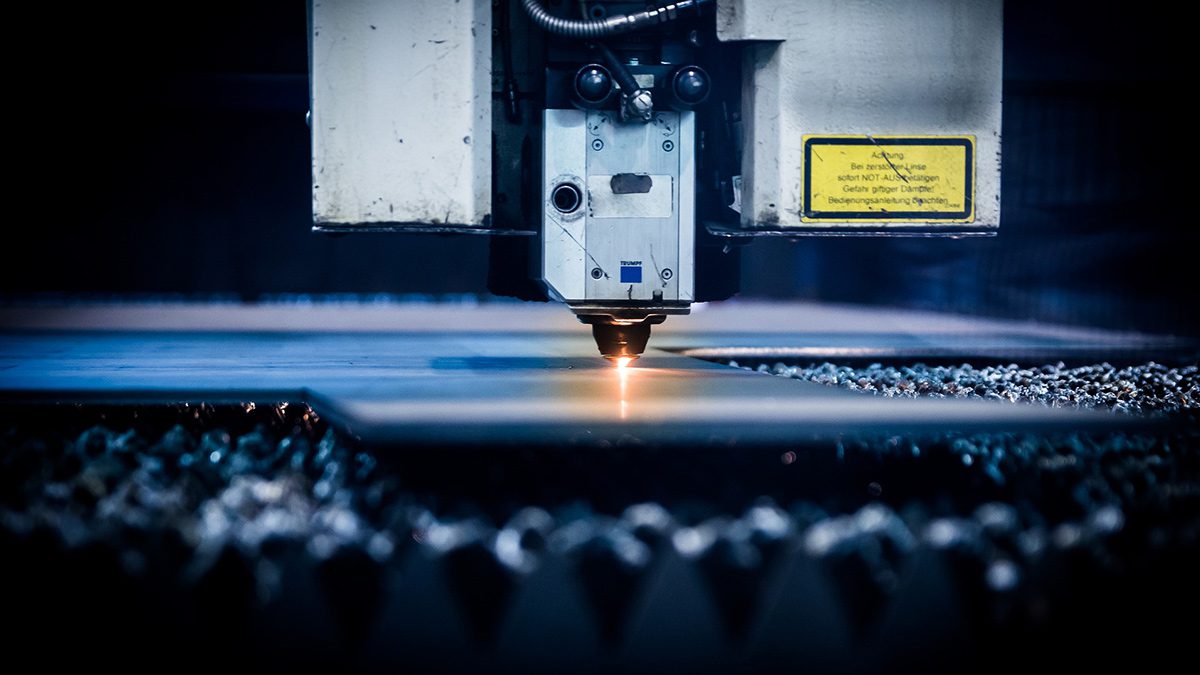

While the technology behind laser etching and laser engraving is quite intricate, the basic functionality can be explained somewhat simply. These machines utilize high-energy beams to engrave marks into hard materials.

The process begins with a concentrated light beam. This beam is then directed onto one very specific area, known as the focal point. The energy created by this high-energy light beam displaces whatever material is already in the focal point, creating a mark. In laser etching, the mark will be around 0.0001 inches deep. Laser engraving and deep laser engraving are used to create deeper marks of 0.005 inches and beyond.

The result is a well-defined, high-contrast mark that can be used to engrave logos or designs to be read by human eyes. It can also be used to create barcodes and other markings designed specifically to be recognized by machines.

British Laser Etching

There are many options available for laser etching machines, and many of these will provide the high-quality results required for its various uses. However, as stated above, a few British made laser etching systems have begun to set themselves apart from much of the global competition.

Systems such as Needham’s N-Lase, which you can read more about at https://www.needhamlaser.com/, Boss’s CO2 line and others have paired advanced features with high quality and affordability. If you live in the UK and are looking to keep your business within the confines of the Queen’s dominion, you are likely to have plenty of tremendous options available.

Choosing the right systems

When shopping for the right laser etching system for your business, there are a few key areas to take into account. While your specific needs and priorities will vary, a few important factors to consider include:

- Whether the machine comes with all you will need or if additional pieces/systems will be required

- The versatility of the machine and what it does well

- The speed of the machine

- Wireless, Bluetooth and other features

- Cost of the systems

- Reliability and reputation of the brand

Choosing the right system can be a great investment that leads to increased success for your business. The wrong model can become a financial and personal burden, with repairs, returns and additional costs in the future.

No comments